Verify high frequency signal integrity on printed circuit boards

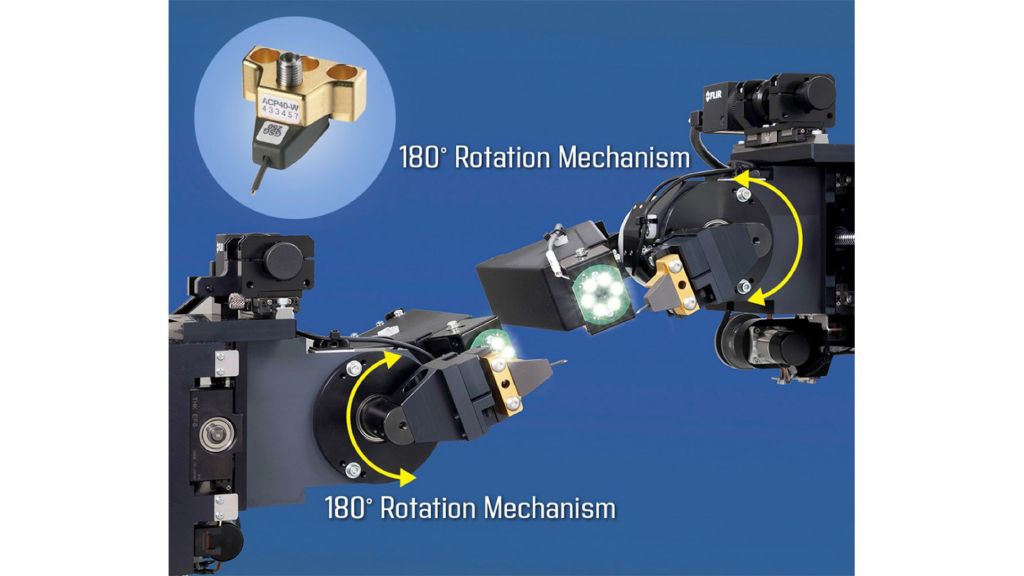

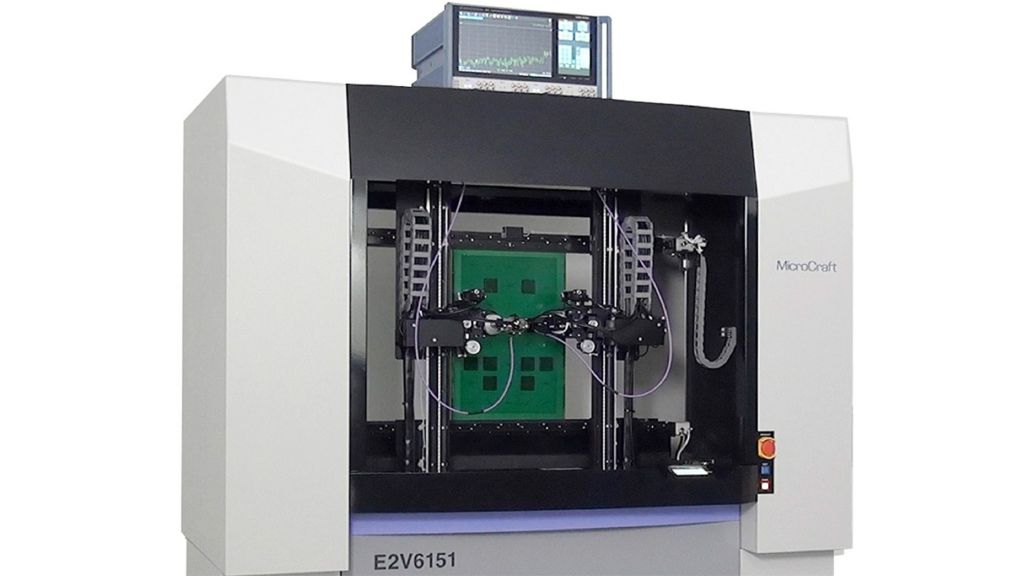

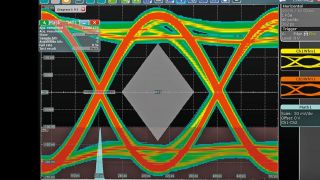

Over the past few years, electronics developers have developed a variety of approaches to avoid interference on high-speed signals on printed circuit boards. However, with increasing complexity and frequency, PCBs set new limits, supporting frequencies of 40 GHz and higher. Driven by the fast growing 5G market, today’s digital systems operate in these high frequency ranges that come with completely new challenges. With slope steepness’s of just a few picoseconds, any discontinuity in the impedance and impairment of the inductance or capacitance on the PCB or back drill defects on the PCB can have a massive impact on the signal quality. The industry recognizes that there is a growing need for functional high-speed testing of PCBs. The MicroCraft® E2V6151 series combined with an R&S®ZNB vector signal analyzer delivers a fully automated solution.