Rohde & Schwarz solution

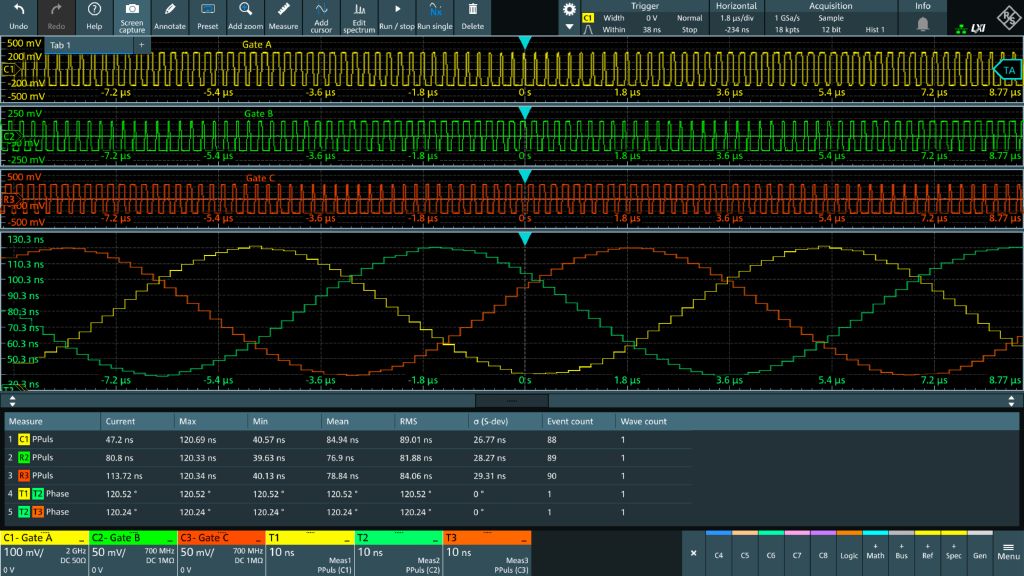

Different equipment is needed for precise results when dealing with such varied measurement requirements. Power analyzers, low frequency vector analyzers or bus decoders can all help with accurate measurements. Oscilloscopes also play a unique role by visualizing time and amplitude relationships, while offering many tools such as FFT, math functions, harmonics analysis, digital communications protocol decoding and frequency response analysis.

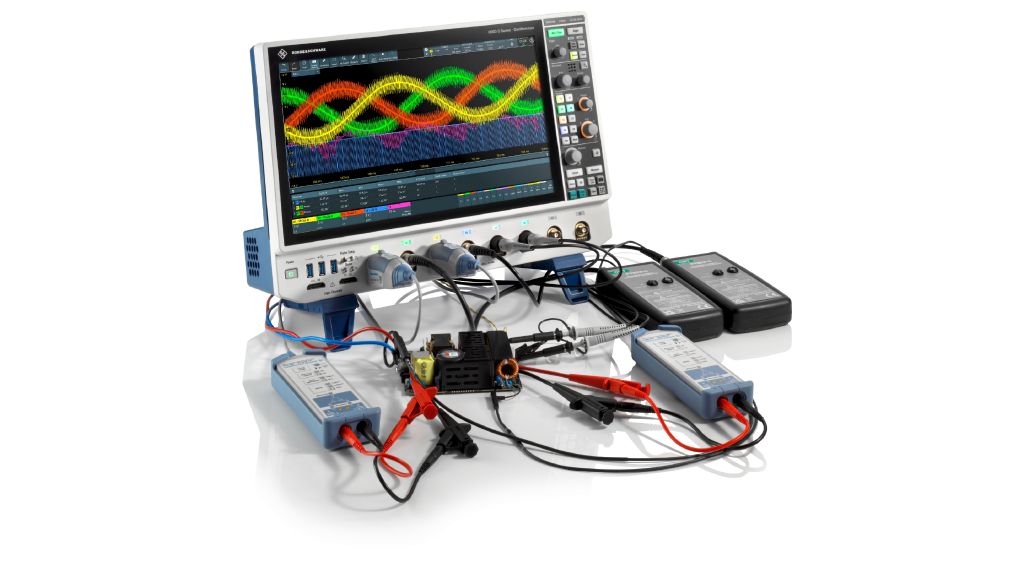

As a next generation oscilloscope, the MXO series excels at electric drivetrain optimization by providing basic time analysis, the fastest available waveform acquisition, 18-bit HD resolution, ultra-fast FFT spectrum capabilities and very deep record lengths. The MXO 5 series is the first eight-channel oscilloscope for three-phase analysis where voltage and current are measured concurrently.

Benefits

- 4.5 million waveforms/s: highest capture rate up to 99 %

- 18-bit HD mode: most precise and accurate available

- 400 Mpoints/500 Mpoints per channel: maintain high sample rates for longer

- 45 000 FFT/s: responsive spectrum for EMI analysis

- Digital trigger: highest available trigger sensitivity of 0.0001 div