Rohde & Schwarz solution

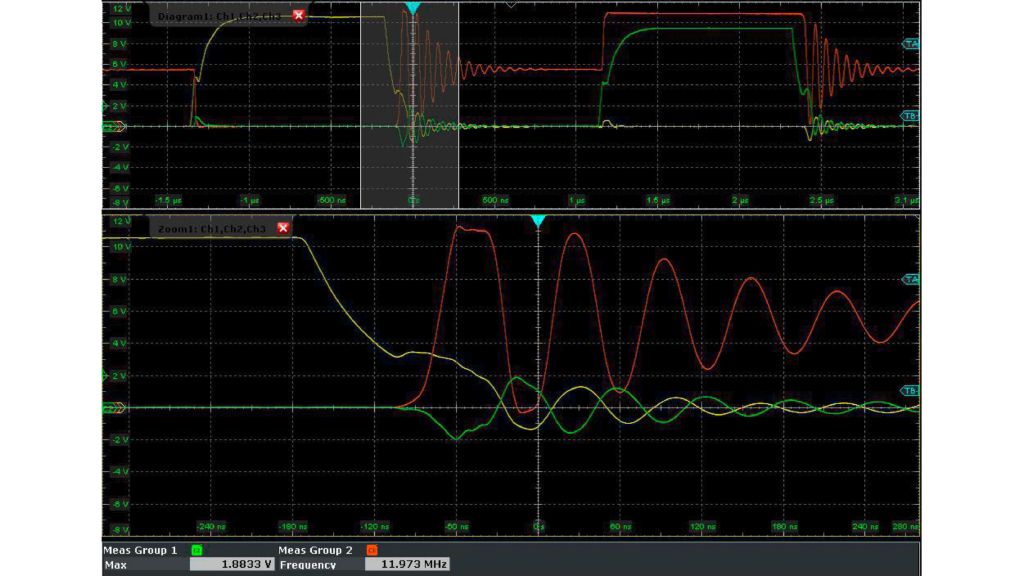

The R&S®RTO and R&S®RTE oscilloscopes offer an advanced, easy-to-use digital trigger unit. In contrast to analog trigger units, the digital trigger unit uses the sampling values of the acquisition paths to decide on trigger events in the digital domain. Users do not have the disadvantages of a separate analog trigger path as used in conventional oscilloscopes.

The advantages of digital triggers for identifying critical operation points

The benefits of the Rohde & Schwarz solution are:

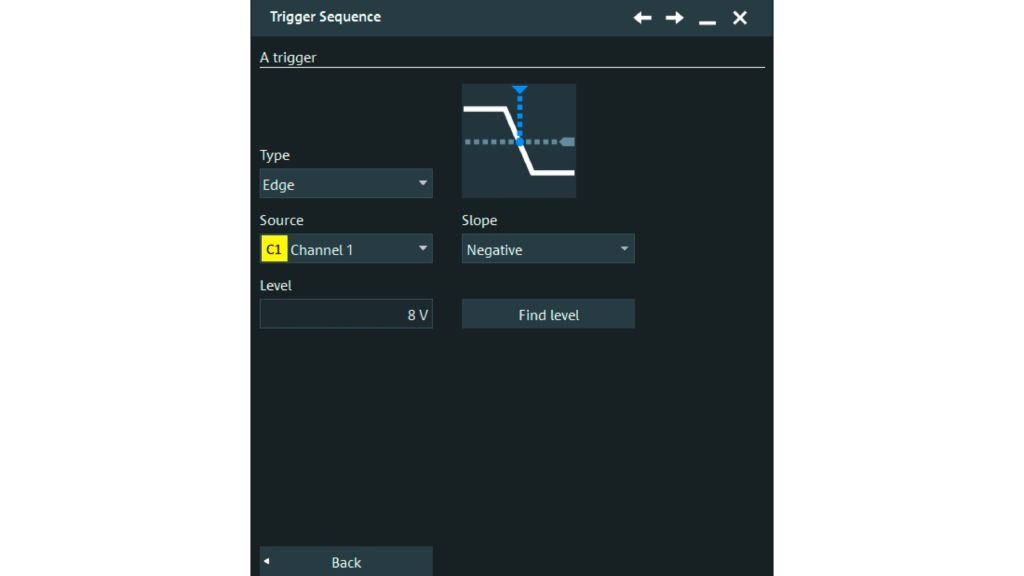

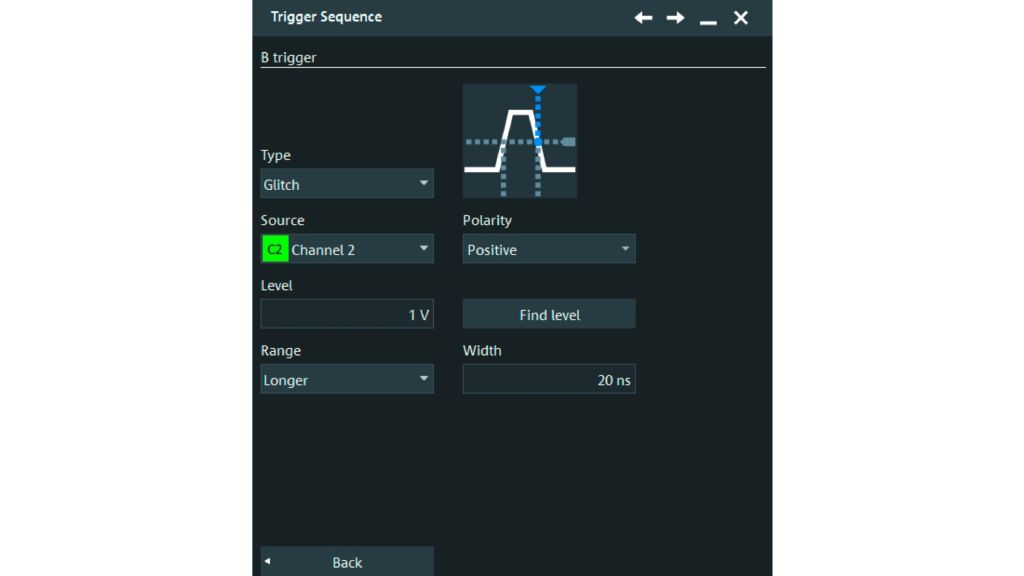

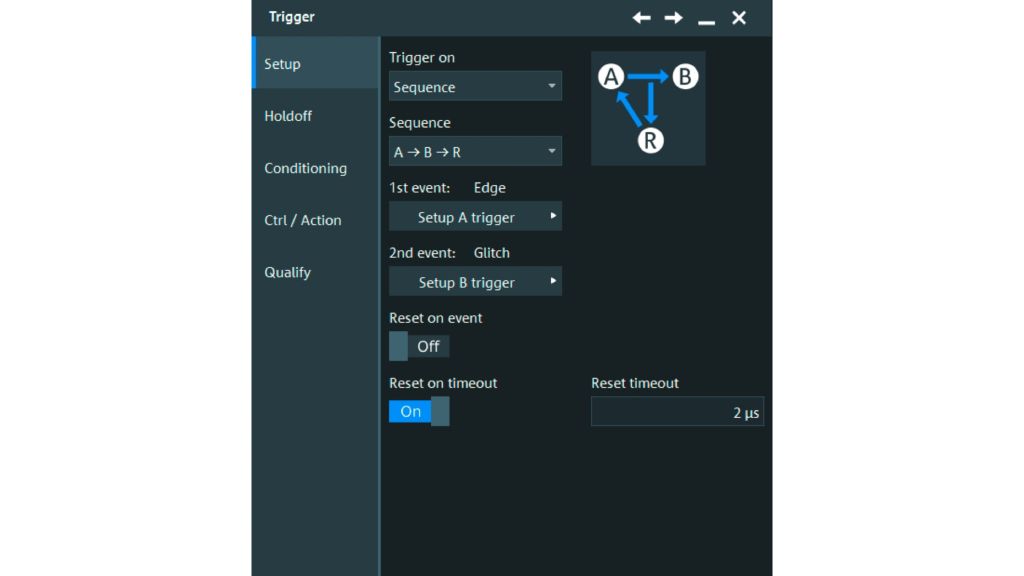

- High flexibility in setting up complete real-time A/B/R trigger conditions

- Individual setting of the trigger hysteresis to optimize the trigger sensitivity for the respective signal

- High trigger sensitivity at full bandwidth to capture small, unwanted glitches

- Very low jitter values for stable triggering

When adjusting the trigger value for the high side gate signal to the largest acceptable value, users can easily identify any switching event that violates this condition, i.e. bears the risk of a shoot through. Thanks to real-time operation, no critical event is missed. Operating the DUT at different load and environmental conditions during verification tests makes it possible to identify critical conditions and eliminate the risk of a shoot through.

Measurement setup

To verify the risk of shoot-through events, the gate to source voltage on the high side and low side switch has to be simultaneously measured. Users have to make sure there are no glitches on the high side gate signals exceeding a predefined voltage level in order to prevent the corresponding transistor from accidentally being turned on. This task requires a complex trigger setup and very high trigger accuracy, and the trigger threshold must be precisely defined.