R&S®ESSENTIALS | Digital oscilloscope and probe fundamentals

How to use your oscilloscope probe: oscilloscope probe tips

Author: Paul Denisowski, Product Management Engineer

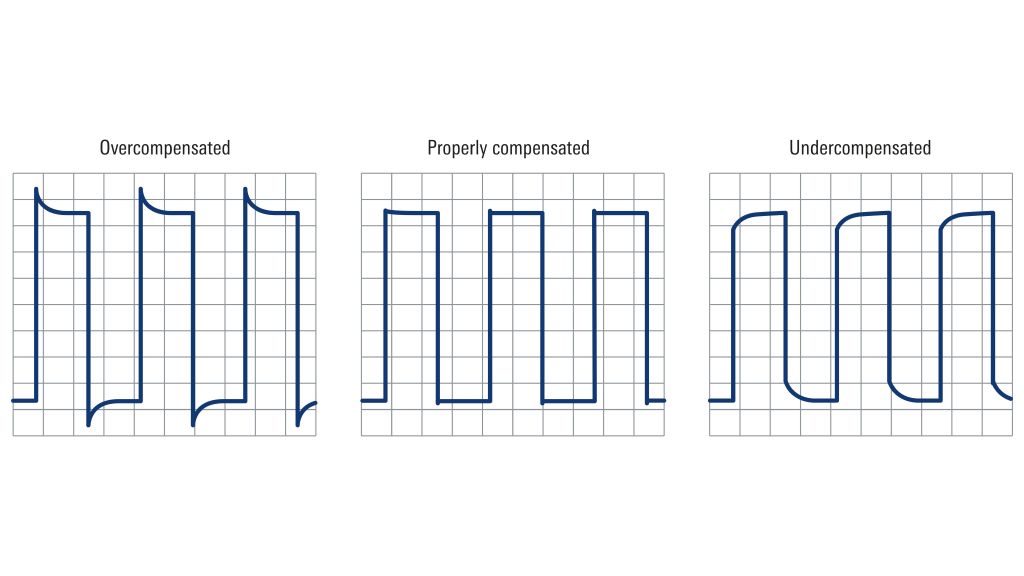

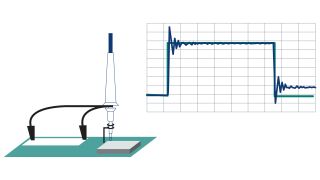

Get the most out of your oscilloscope with our basic guide to best practices for oscilloscope probing. We’re going to go over eight important tips to ensure accurate reliable measurements. From compensating passive probes to degaussing current probes - we've got you covered.

Oscilloscope probe types

There are two main types of oscilloscope probes: active and passive. The choice between the two boils down to a trade-off between simplicity and sophistication.

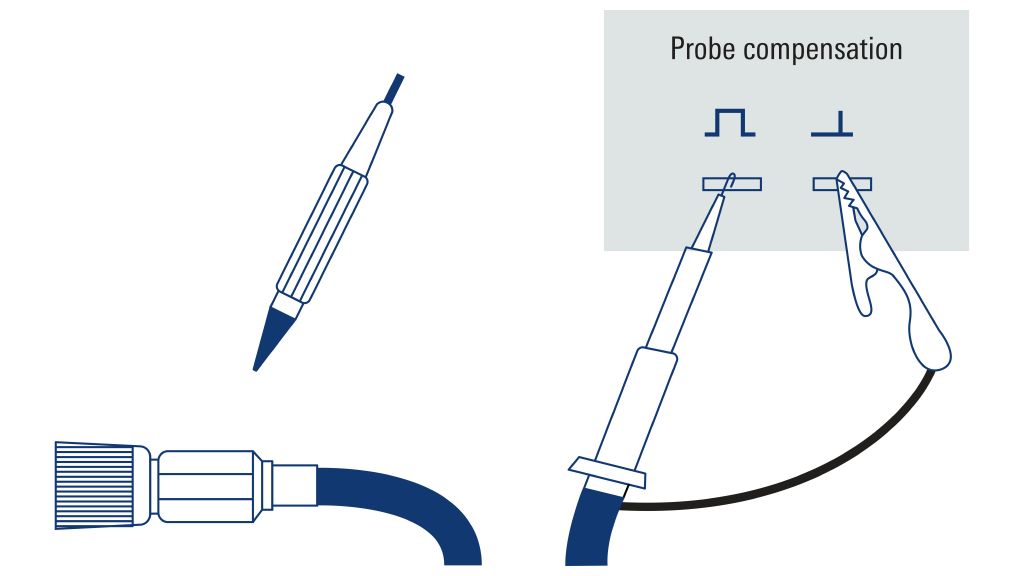

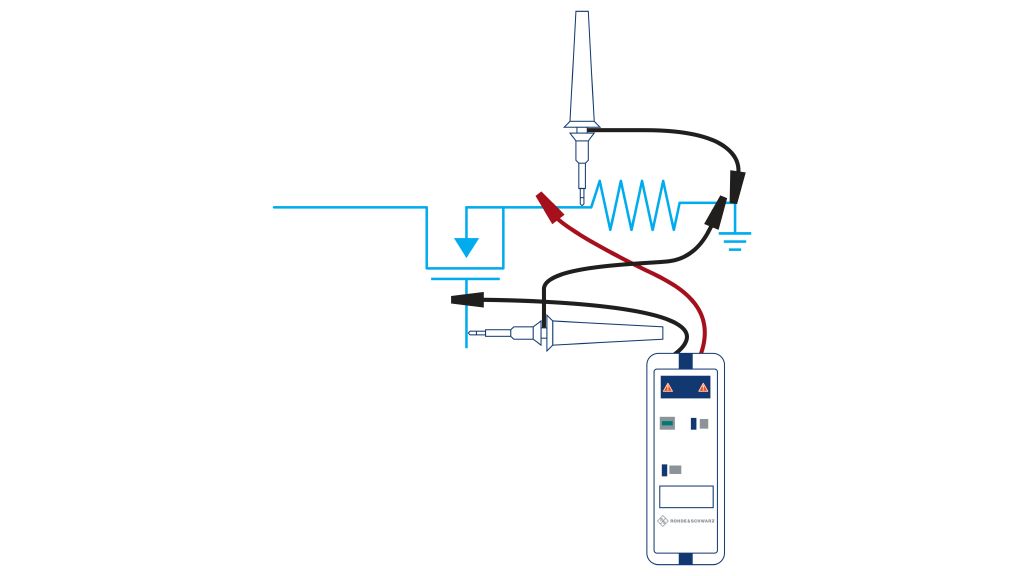

Passive probes are more straightforward - they require no external power source and are cost-effective. They are reliable, rugged and very easy to use: connect to the scope, attach the ground lead, and you’re ready to go. A set of passive probes often comes bundled with oscilloscopes, making them readily available for a variety of basic measurements.

Active probes, on the other hand, bring a higher level of precision and performance to the table - or rather, the bench. As their name suggests, these probes are equipped with active components that allow them to handle high-frequency signals. This also means that they come with a higher price tag, but their greater flexibility and enhanced sensitivity make them indispensable for applications that demand high accuracy.

Ultimately, the choice between passive and active probes depends on the specific requirements of the task at hand. It's a matter of balancing the demands of the measurement with your budget and desired level of performance.