T&M solution

Rohde&Schwarz offers a robust and compact solution to provide conducted immunity tests, covering both the substitution and the closed loop method.

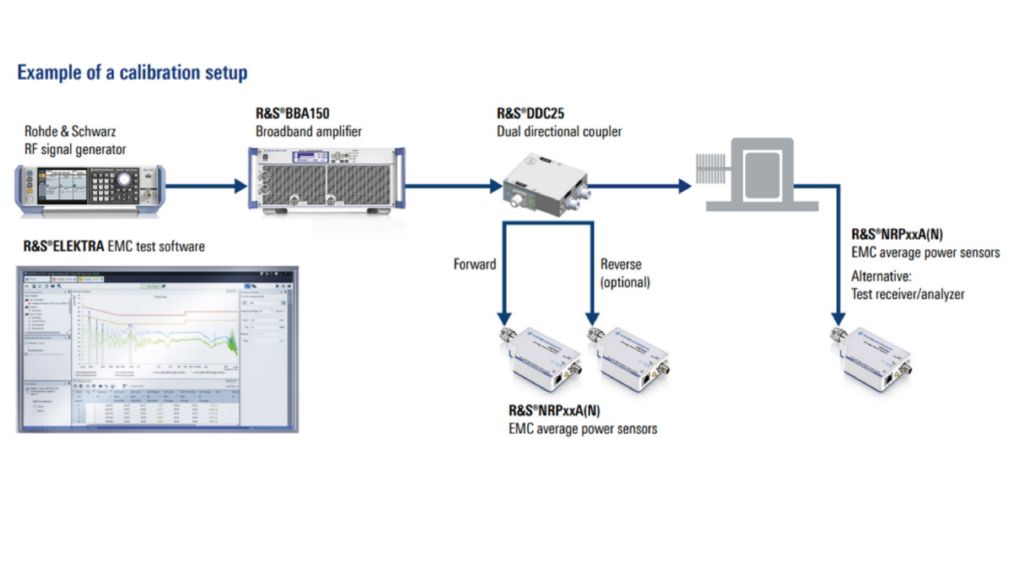

An R&S®SMB100B, R&S®SMCV100B or R&S®SMC100A signal generator delivers the required AM test signals in the frequency range from 4 kHz to 400 MHz.

A downstream broadband amplifier from the R&S®BBA150-AB series supplies the necessary CW output power. The R&S®BBA150-AB broadband amplifiers are single-band, highly linear class A solid-state amplifiers that can handle high mismatch at the RF output. R&S®BBA150-AB models with 75 W, 125 W, 160 W, 200 W and 350 W output power are available as required for the test setup and the test power level.

Two or three power meters are required to monitor the various power levels (e.g. forward power, reverse power)during calibration and testing both for the substitution and the closed loop method. To this end, R&S®NRP6AN high-end average power sensors from Rohde&Schwarz are integrated in the compact test system. Two of these sensors can be connected to the amplifier’s internal R&S®BBA-B140 RF directional coupler or to an R&S®DDC25-AB55 calibrated directional coupler.

The Rohde&Schwarz R&S®EMC32 and R&S®ELEKTRA EMS test software packages enable fully automated calibration and testing including DUT monitoring. A test report is generated that provides all the necessary information.