T&M solution

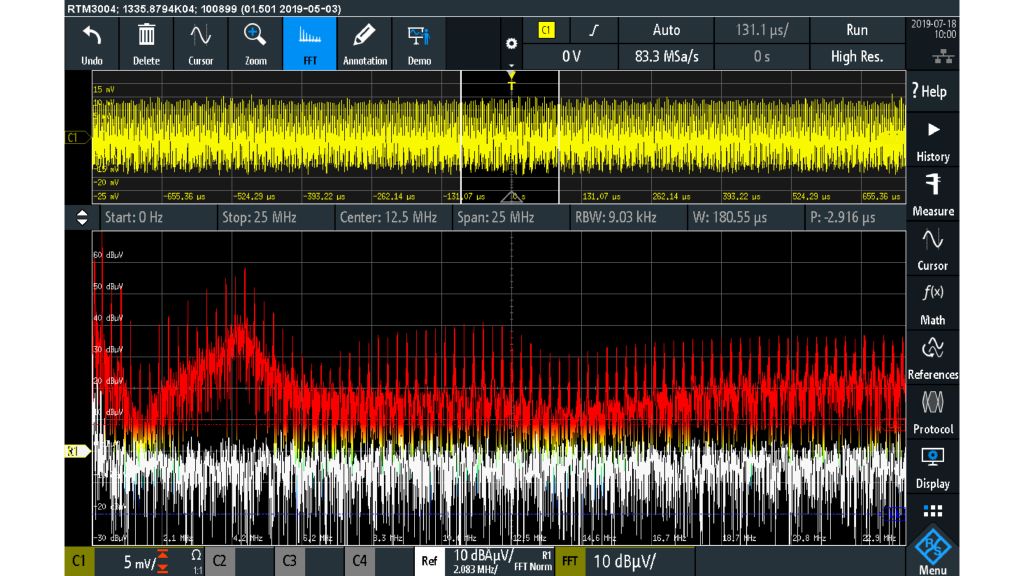

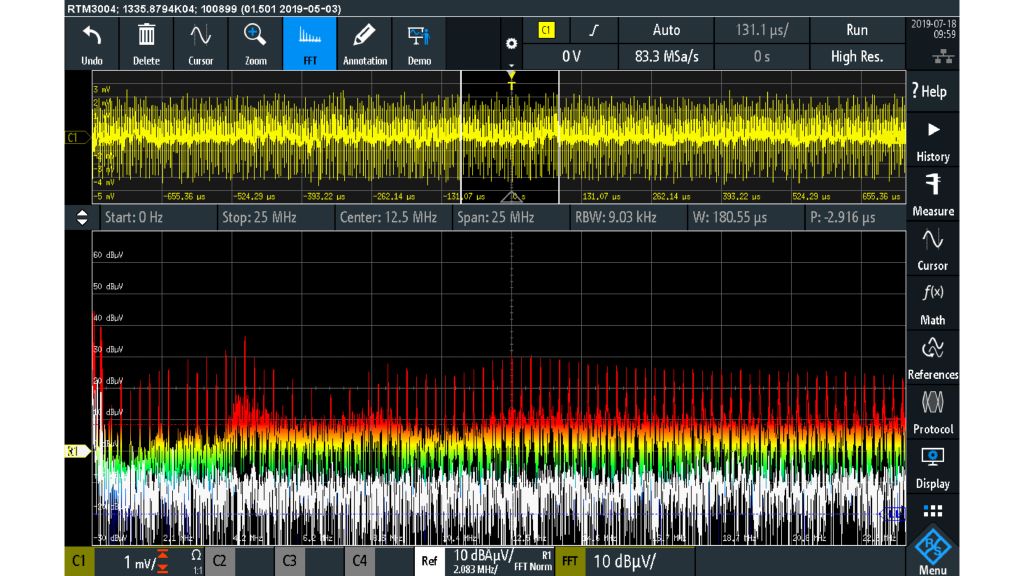

Rohde & Schwarz oscilloscopes offer a powerful, easy-touse FFT analysis functionality to measure the magnitude of the frequency component. Users are able to see the time domain related signals at the same time and can therefore correlate unwanted spectral emissions with time domain events. This makes these oscilloscopes powerful standalone instruments for performing early conducted emission tests on power electronics designs. This is particularly helpful when no dedicated equipment such as an EMI receiver is available in the R&D lab to support the precompliance measurement during the design phase.

The earlier EMI compliance is taken into account, the more likely it will not become an issue at the end of the development process. Uncovering an EMI problem early on is less costly and easier to fix. Since oscilloscopes are typically the main instrument used during hardware development and system testing, they are a valuable tool for EMI related tests in R&D.

Test setup

To measure conducted emissions of a power supply, a line impedance stabilization network (LISN) is required to decouple the device under test from the external power supply. The coaxial output of the LISN has to be connected to the oscilloscope with a coaxial cable with 50 Ohm input impedance activated at the oscilloscope to ensure proper matching. On the oscilloscope, the following steps have to be executed to measure the spectrum:

- Activate the FFT and configure the minimum and maximum frequency and the resolution bandwidth.

- Adjust the vertical sensitivity in the time domain window such that the input channel is not overdriven when the device under test is powered.

- Switch off the power to the DUT to make a reference measurement. This makes sure that you know the noise floor of the setup and that this noise does not come from the DUT.

- Switch on the power again and make a measurement. Verify against known conducted emission limits for the DUT. Take into account any additional attenuation due to the LISN.