Unlock the mystery of quality with real-time microwave imaging

The next step in Rohde & Schwarz excellence

For many years, Rohde & Schwarz has stood for accuracy and is known worldwide for top-tier test and measurement devices. Building on this strong reputation, we introduce the R&S®IMAGER — a game-changer in modern quality assurance.

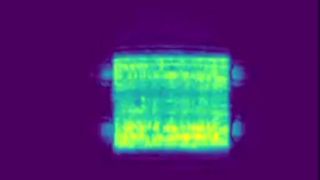

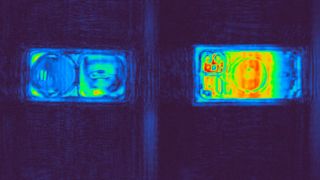

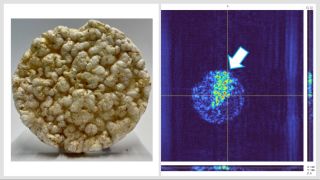

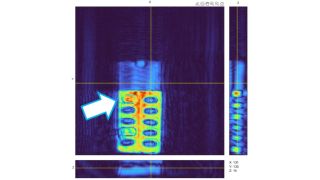

Using powerful real-time microwave imaging, this device does more than just scratch the surface. It lets you see deep into materials, revealing hidden details. Whether it's inspecting food or studying liquids, the R&S®IMAGER is versatile and showcases our deep commitment to quality and new ideas.

"Find what you need." is more than a slogan to us; it's our promise. We're always aiming for precision, whether in advanced electronics testing or novel areas of potential.

As we seek new uses and partners, come with us on this journey where the trusted legacy of Rohde & Schwarz meets the needs of today's world.