Early wafer-level qualification of RF components ensures quality and saves money.

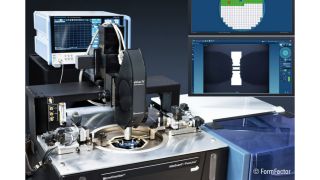

R&S®ZNA vector network analyzer performing on-wafer measurements together with FormFactor SUMMIT200 probe system.

Your task

The fundamental challenge for 5G RF frontend developers is to ensure proper RF performance with respect to frequency coverage and output power while optimizing energy efficiency. In the development of active components such as power amplifiers, low-noise amplifiers and switches, or integrated RF frontend monolithic microwave integrated circuits (MMIC), the first opportunity to investigate your RF design is by testing it right after fabrication of the wafer. To verify your design as early as possible, it makes sense to check the performance and capabilities at the wafer level.

Understanding the quality of wafer runs is also of high interest in production to avoid packaging bad devices. This is especially important when packaging adds significant value to devices. Qualifying devices as early as possible is therefore advisable to minimize cost on non-compliant or faulty devices.

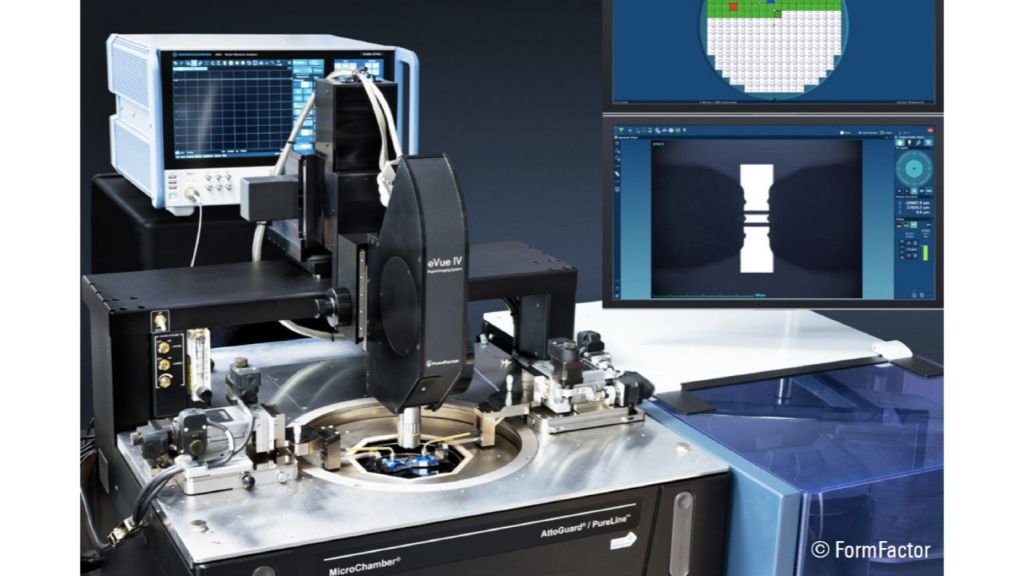

FormFactor InfinityXT RF probes contacting a standard on a calibration substrate.

Rohde & Schwarz solution with FormFactor

Characterizing a DUT at the wafer level requires a measurement system including a vector network analyzer (VNA), a probe station, cables/adapters and wafer probes. Rohde & Schwarz is collaborating with FormFactor to address wafer-level testing. This has led to a combined solution with Rohde & Schwarz supplying the VNA, which is a powerful one-box tester measuring all RF qualification parameters, no matter whether coaxial or waveguide adapters are used. FormFactor addresses the wafer-level device contact with a wide range of manual, semi-automated and fully automated probe systems including thermal control, high-frequency probes, probe positioners and calibration tools.

Continuous wave (CW) signals are typically used to verify RF characteristics. Pulsed signals are also often applied when testing active devices to limit device self-heating. Thermal management is important for two reasons. First, you want to keep your DUT in stable thermal conditions to enable reliable, repeatable and controlled measurements. Second, overheating could damage or destroy your DUT.

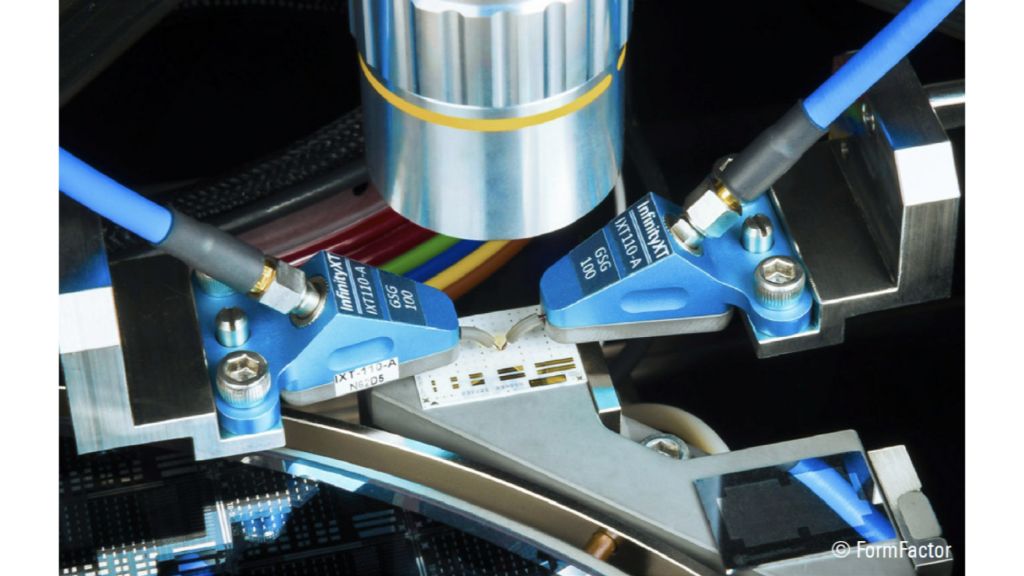

R&S®ZNA43 selected as VNA in FormFactor WinCal XE software.

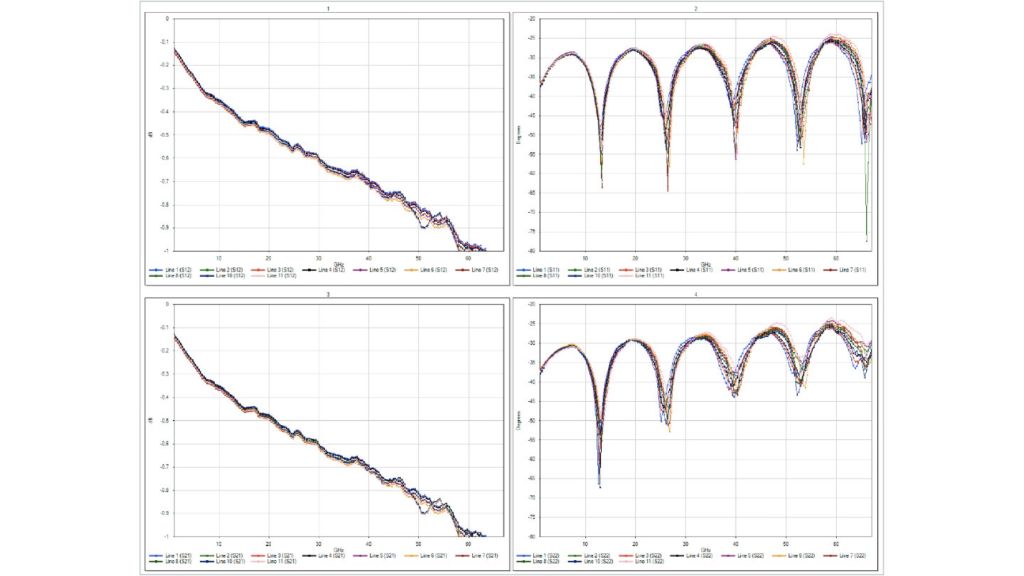

On-wafer RF test setups cannot rely on the coaxial or waveguide calibration methods and standards typically used with VNAs. To enable accurate and consistent calibration results at the wafer level, you must use probe-tip calibration techniques performed on calibration substrates. These substrates include lumped-element impedance standards, calibration and verification lines, probe alignment marks, as well as an area for probe planarization. Calibration of the complete test system including the R&S®ZNA is fully supported by the FormFactor WinCal XE calibration software. When applying the calibration data to the VNA, you are moving the measurement plane down to the wafer to the tips of the RF probes used. This gives you a fully calibrated VNA test system for on-wafer measurements.

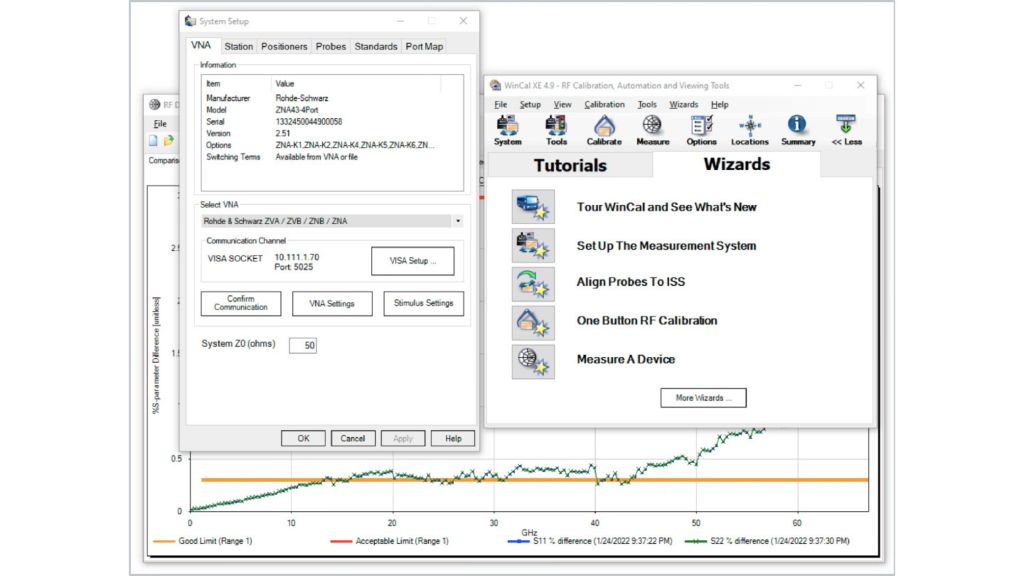

Measurements of multiple 40 ps line standards performed with R&S®ZNA67 and FormFactor Summit200 probe system.

Application

The on-wafer test solution provides full RF performance characterization of your device under test. The solution gives you access to all of the VNA’s test capabilities thanks to the fully calibrated setup. General S-parameter tests allow the characterization of filters and active devices. Distortion, gain and intermodulation can also be measured to qualify power amplifiers. Frequency-converting measurements on mixers with phase characterization across the DUT’s bandwidth are another example of the measurement applications supported by the on-wafer test solution. Thanks to the fully calibrated setup, all results can be directly taken from the VNA without postprocessing as the calibration data is applied directly to the VNA.

On-wafer device characterization enables early design verification during development, as well as product qualification and verification during production. The combined solution from Rohde & Schwarz and FormFactor makes it easy to characterize and qualify your device under test.