Built-in measurements

Rohde & Schwarz DC power supplies come with a range of built-in measurements that can in many applications replace additional instruments such as an external oscilloscope´ or a multimeter to measure e.g. instantaneous power. Since no extra load is connected to the power supply, no additional burden voltage needs to be taken into account – a major advantage offered by built-in measurements. In addition, they are very convenient and simplify the setup.

Vector signal generators provide further analysis functions such as statistics, including min./max. and average values for power, voltage and current as well as an energy count.

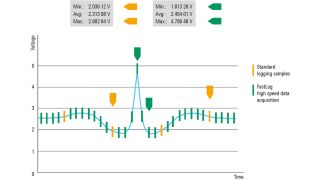

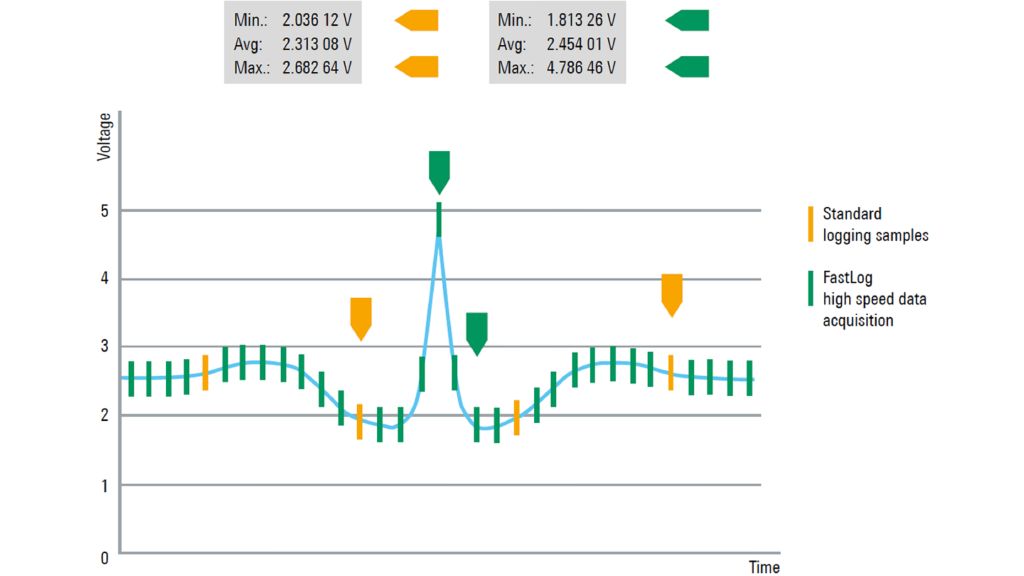

High-precision power supplies such as the R&S®NGL200, R&S®NGM200 and R&S®NGU offer measurements with 6½ digit resolution. If in addition a power supply features a high-speed ADC, like with the R&S®NGM200 and R&S®NGU, even fast transients can be detected and measured.

Measured values can be recorded versus time using the logging functions. Some power supplies with a large display also offer graphical analysis functions.

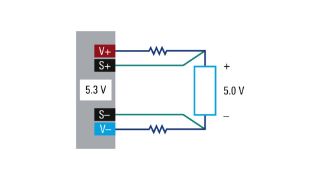

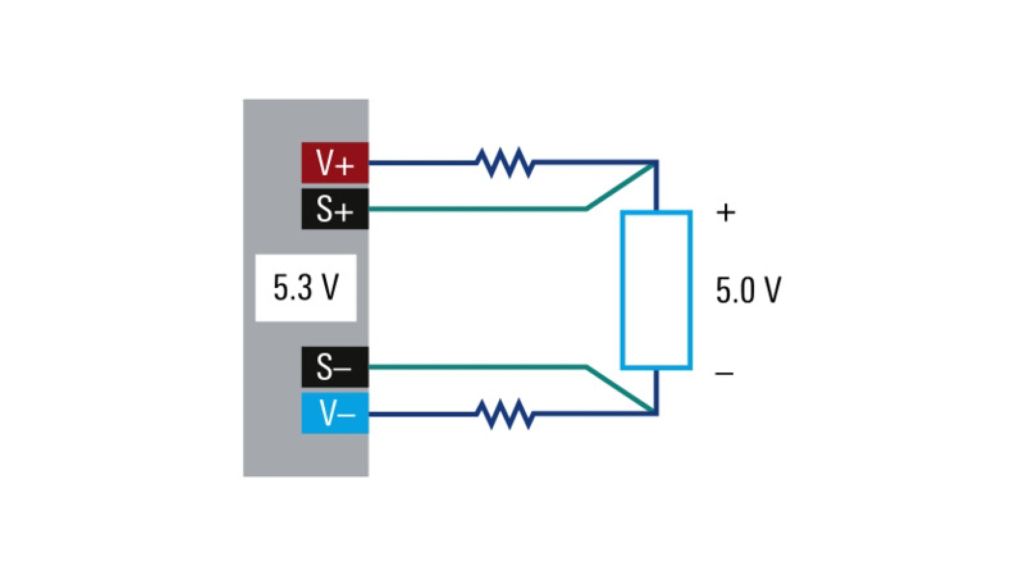

Digital voltmeter functionality

Some power supplies can be equipped with an optional integrated digital voltmeter (DVM), which even further expands the instruments’ built-in measurement capabilities. The DVM allows measuring the voltage at any desired point in the DUT circuitry. This renders an additional multimeter superfluous.

The DVM option is available for all R&S®NGM200 models and the R&S®NGU201.