Qualcomm beam characterization and beam verification

Measuring and optimizing the characteristics of individual elements within an antenna array for beamforming performance of Qualcomm 5G mmWave modems SDX50 and SDX55.

Measuring and optimizing the characteristics of individual elements within an antenna array for beamforming performance of Qualcomm 5G mmWave modems SDX50 and SDX55.

5G at mmWave range enables significantly higher data rates. However, signals traveling at high frequencies are prone to high path loss. Hence, beamforming technology is crucial to boost signal gain in order to compensate for the path loss.

In beamforming, individual antenna elements’ phase and amplitude correlate with each other to form the ideal beam. Therefore, characterizing and verifying each antenna element is critical to the overall beamforming performance.

This process is typically carried out during the development of a new UE due to a number of factors that will affect beamforming performance. These factors include UE housing, modem, antenna or even hardware layout. This is why a “golden device” is characterized and verified before mass production and device samples are verified during production. Beam characterization can basically be seen as the FR2 equivalent of UE calibration in legacy technologies.

The entire process of beam characterization and verification is automated by Qualcomm Development Acceleration Resource Toolkit (QDART) using Qualcomm approved instrumentation such as the R&S®ATS1800C antenna test chamber and the R&S®CMP200 radio communication tester.

Procedure

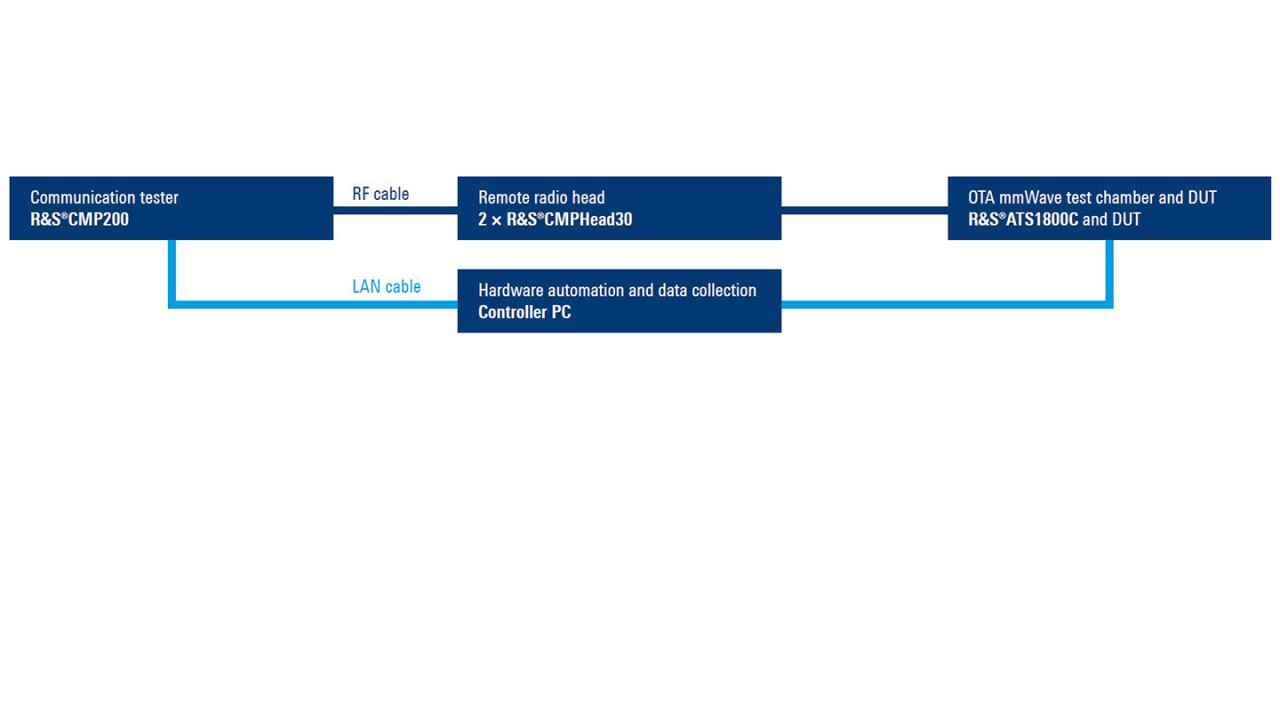

The illustration below shows the full hardware setup for both beam characterization and beam verification. The DUT is mounted on the 3D positioner within the R&S®ATS1800C chamber and measurements are performed over the air with the R&S®CMP200 radio communication tester while test procedures are automated by QDART on the controller PC. In addition, QDART is also responsible for configuring the DUT and collecting measurement data.

In beam characterization as well as beam verification, the DUT is configured to transmit signals while the R&S®ATS1800C 3D positioner rotates in both axes to determine the beam characteristics at all required DUT orientations. The signals are measured by the R&S®CMP200 radio communication tester and the results are stored in the controller PC for further processing.

The goal of beam characterization is to identify beam characteristics so that a calibration matrix can be generated and programmed into the DUT. Subsequently the beam characteristics are once again investigated in the beam verification process. This time, the measured signals are compared with benchmark numbers in order to verify the beamforming performance of the DUT. The same calibration matrix can then be applied to the bulks of DUTs being manufactured in production, and samples can be checked using the beam verification process.

R&S®CMP200 radio communication tester and R&S®CMPHEAD30

R&S®CMP200 radio communication tester

The R&S®CMP200 is an IF tester that combines vector signal analyzer and ARB based generator functionality. Thanks to the innovative split concept, high-accuracy measurements at mmWave range are available with the R&S®CMP200 and R&S®CMPHEAD30.

R&S®ATS1800C CATR based compact 5G NR mmWave test chamber

R&S®ATS1800C CATR based compact 5G NR mmWave test chamber

The R&S®ATS1800C has a unique vertical CATR design that not only has a high quiet-zone-to-footprint ratio, but also allows mounting of heavier DUTs as compared with horizontal chambers. Hence, smartphones, tablets or even laptops can be mounted and tested on the high-speed rugged 3D positioner.

Key features and benefits

Beam characterization and verification is crucial for 5G mmWave devices. It represents the equivalent of UE calibration in legacy technologies. Besides having the full solution validated and recommended by Qualcomm, the combination of the R&S®ATS1800C CATR based compact 5G NR mmWave test chamber and the R&S®CMP200 radio communication tester together with the R&S®CMPHEAD30 enables accurate, quick and efficient beam characterization in an ideal and compact environment. As an international company, Rohde & Schwarz provides worldwide service and support to get your beam characterization setup up and running and keep it operational at the highest performance and quality level.