1. Basics of Instrument Remote Control

The growth in productivity has led to a dramatic improvement in the quality of our lives over the last several decades. Being able to produce more with fewer resources in a shorter amount of time makes our labor more valuable and the product of our labor cheaper. One of the factors attributing to the growth of productivity is automation.

Automation in the Test and Measurement industry has become so widely used, that nowadays practically every modern measurement instrument can be controlled remotely. Rohde & Schwarz invests significant resources to supply our instruments with wide variety of high-performance connectivity options. Many of our instruments are not even equipped with a screen since their main purpose is remote control operation in an automated test setup.

Main advantages of automating a measurement task:

- Automation saves time. If you invest time into developing a remote-control application, repeating the same measurement task takes significantly less time.

- Instruments can be operated from a distance. For example, testing a DUT (Device Under Test) in a temperature chamber or an anechoic RF chamber.

- Measurements are repeatable. Measurement tasks are always performed with the defined procedure. Once correctly debugged, they always deliver repeatable results. This contributes to higher test confidence.

- Automated systems are easier to expand. If structured correctly, you can perform the same measurement on more DUTs. For example, a four channel oscilloscope can help to test four DUTs. If you need to connect more DUTs, you can use an automated switching unit.

- Protocolling test results. Many programming environments offer ready-to-use toolboxes for reporting and processing test results.

- Automation saves you a lot of routine work and lets you focus on creative parts of your project instead.

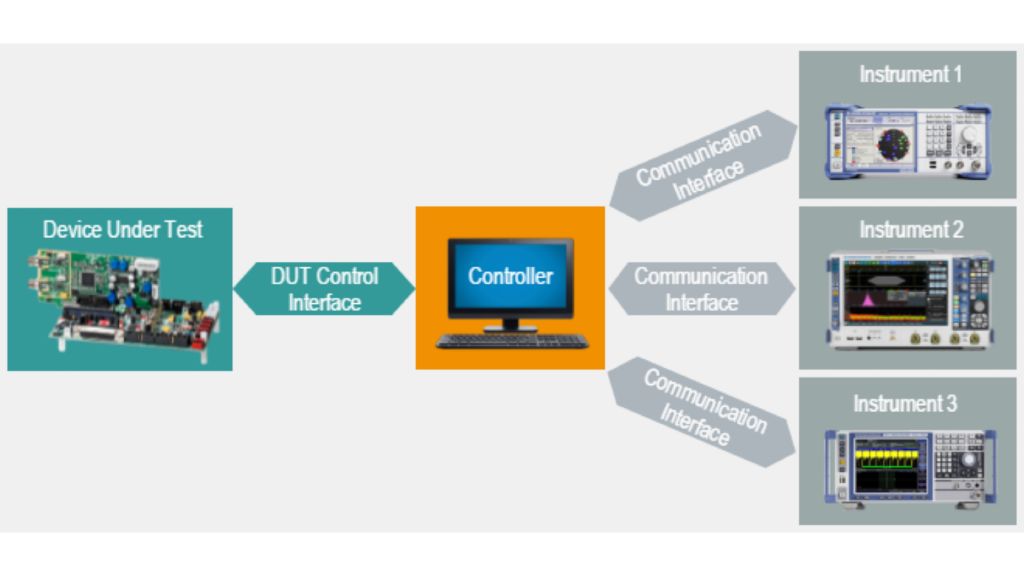

The equipment used to perform the automated tasks is called automated test equipment (ATE). It consists of:

- A controller, usually a PC, a notebook or an industrial computer.

- One or more measurement instruments capable of remote control operation.

- A physical communication interface between the controller and the measurement instrument(s).

- Remote control software running on your control computer.

- Device Under test (DUT).