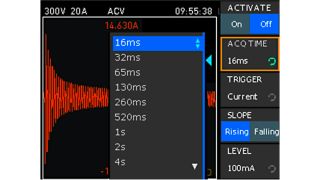

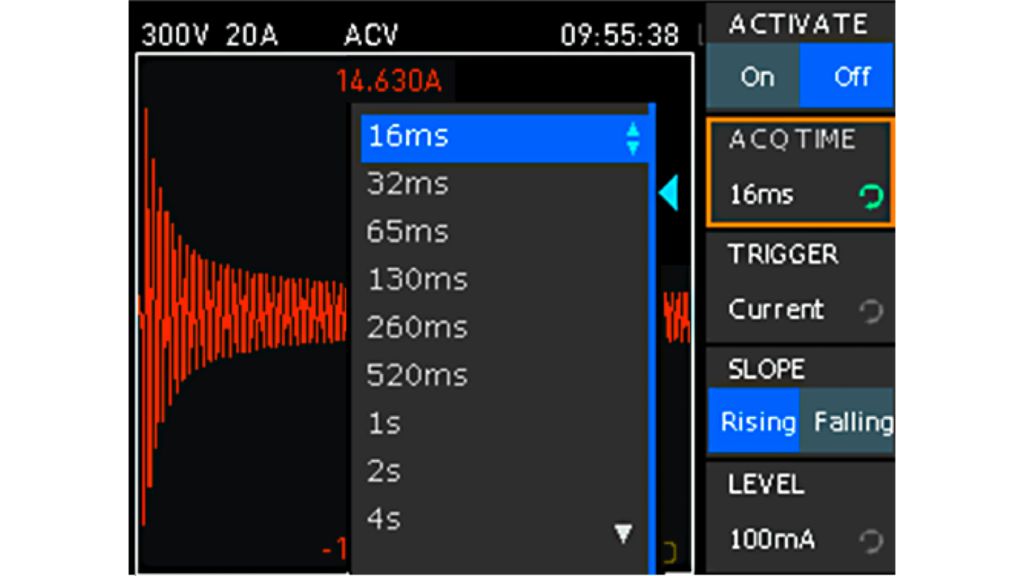

Inrush view

The Inrush view provides more precise analysis of switch‑on operations (e.g. to determine the melting integral of a fuse). Non‑compressed acquisition of up to 8192 voltage and current points is possible with a logging period from 16 ms to 67 s. A number of trigger options are also available. The ACQ TIME button can be used to adjust the recording time as needed.

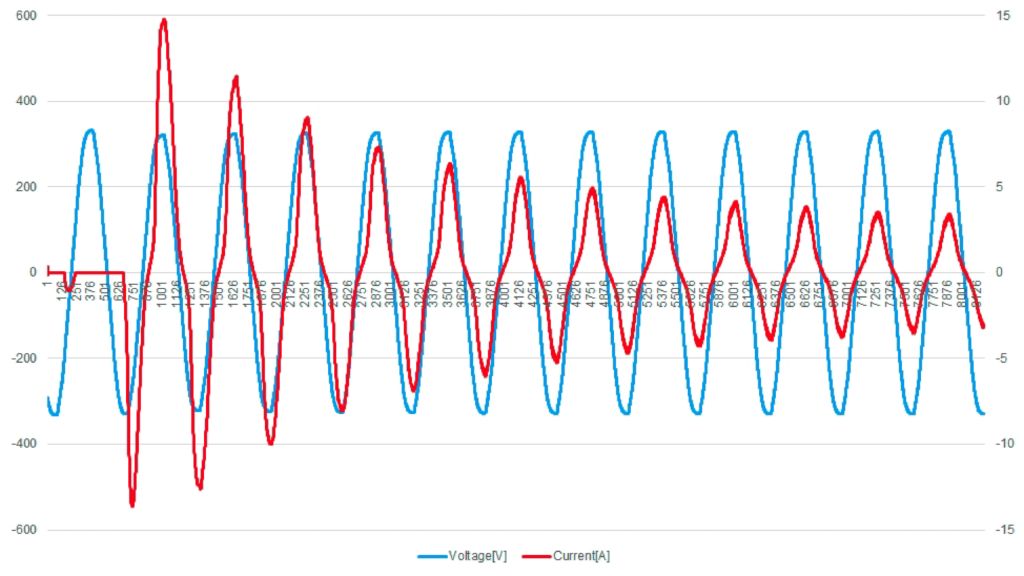

Measurement documentation

After a successful measurement, the precise data can be conveniently saved to a USB flash drive as a configurable CSV file. The data can then be evaluated on a PC using standard data processing software.