Rohde & Schwarz solution

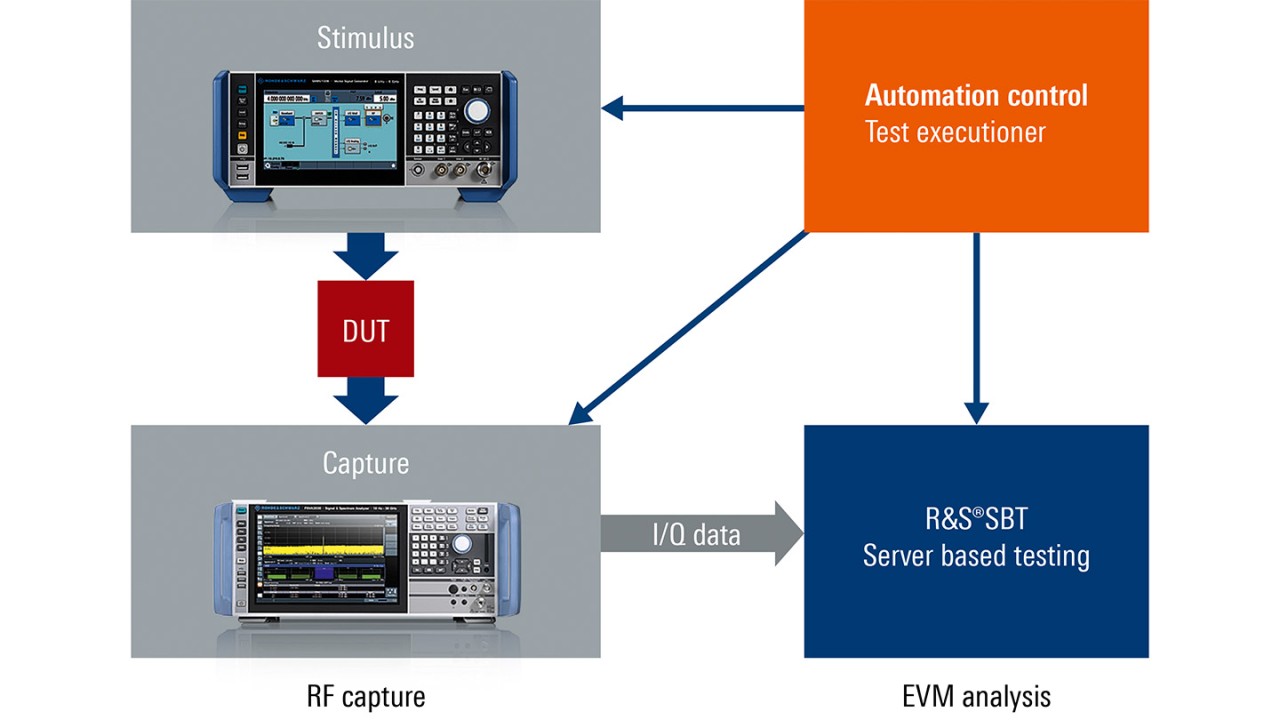

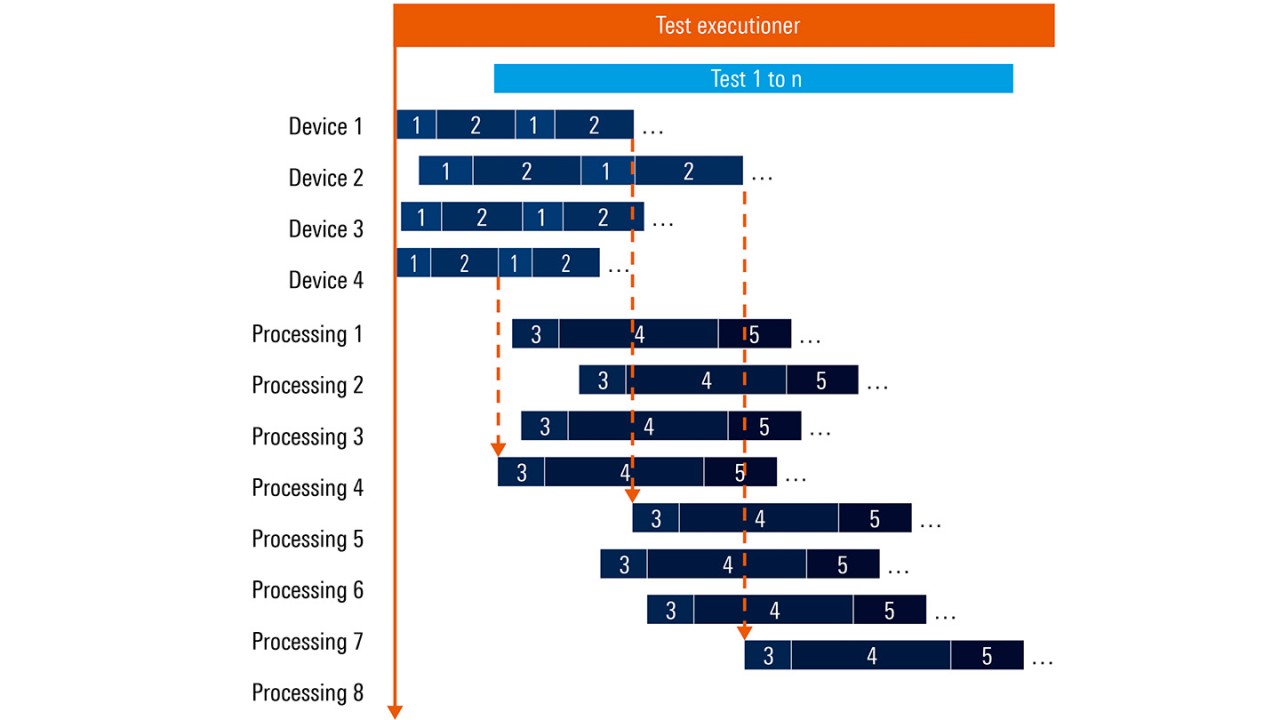

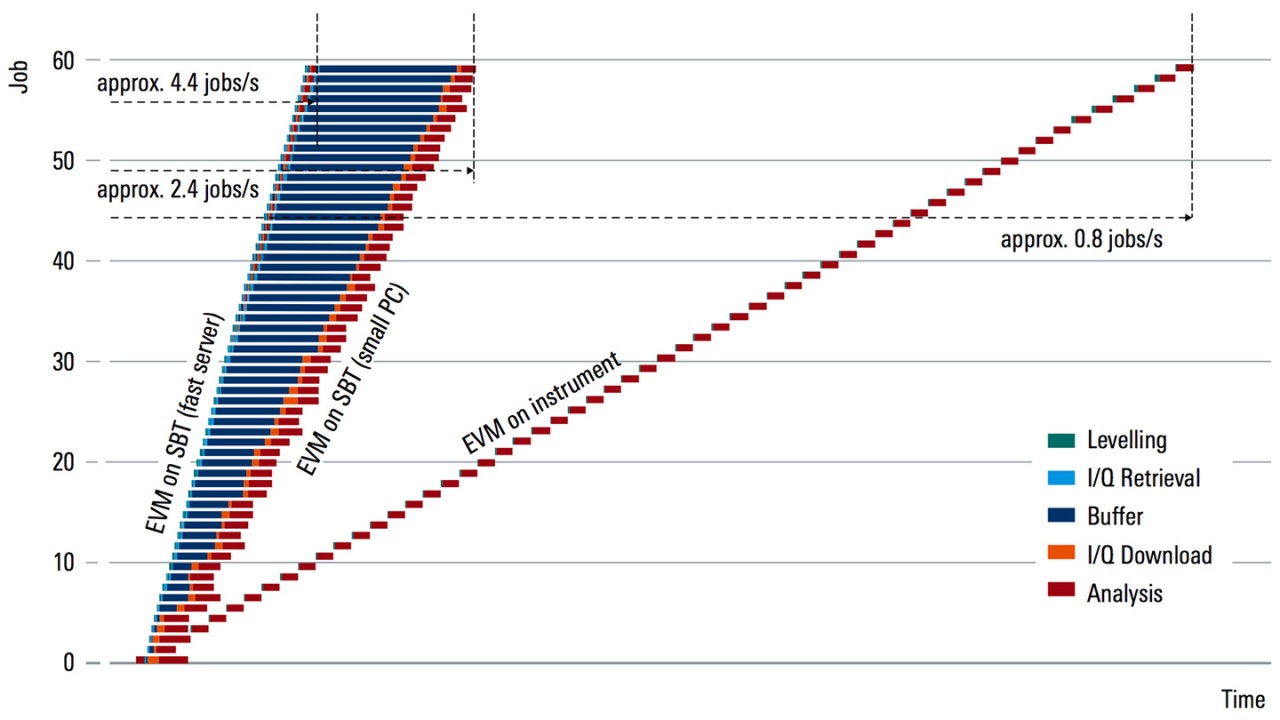

Parallel execution of test jobs using fast RF equipment together with multithreaded optimized signal processing based on our R&S®SBT server based testing routines is sufficient for both the speed of execution and for scalable tests to improve instrument utilization.

Let’s take a step-by-step look

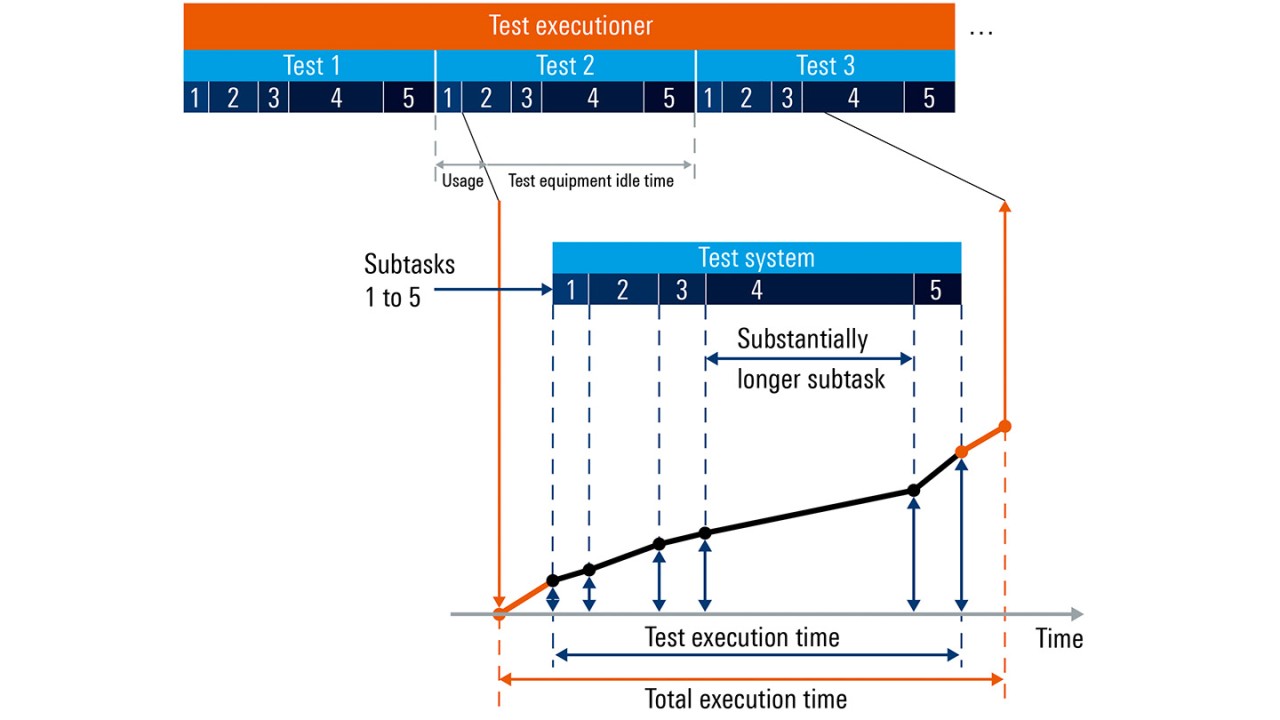

The traditional characterization and production routines go through each test step sequentially. After one step is completed, the next step follows. Improving test times is often accompanied by reduced test depth or accuracy, which may result in an increased failure rate in later operation.

Without sacrificing accuracy while still maintaining a needed quality level, every step or subtask has a minimum time tag. In RF measurements, there is typically the tradeoff between a larger dynamic range and faster sweep times, which translates directly into measurement accuracy versus test speed.

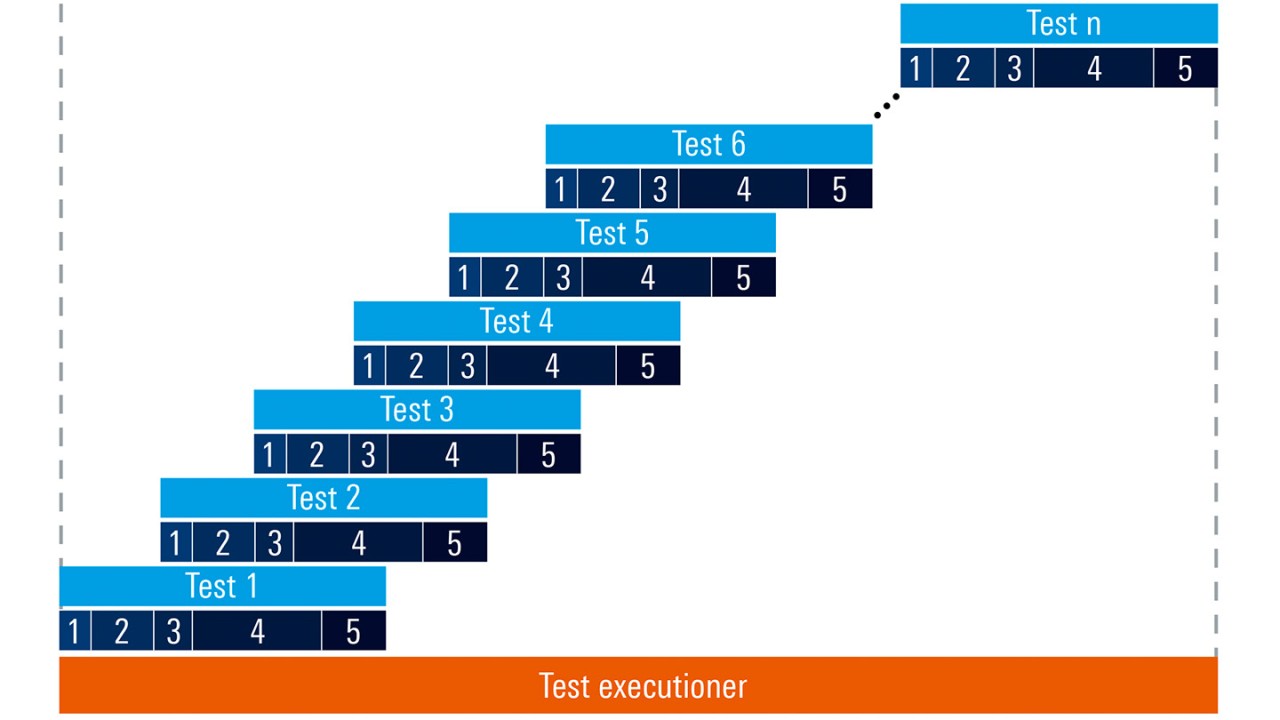

For a typical characterization over amplitude and frequency, the same test is performed at each step. It may be worth examining the duration of each subtask to find out where time is lost.