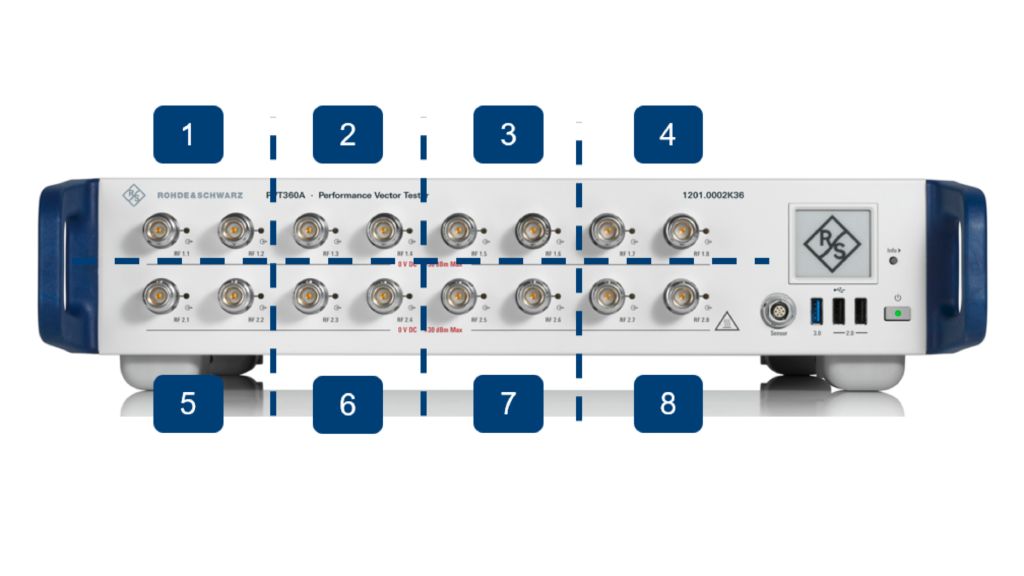

In a production setup, where the test devices are put into a test fixture, the indexing time, i.e. the handling time to bring the devices to the load board on the test station, can significantly contribute to the overall production test time. The test fixture often supports multiple devices that are loaded in one process step before the functional and performance tests. To connect the fixtures to the test instruments, a switch matrix is used to map the fixture ports to the test ports of the instruments. The R&S®PVT360A already includes 16 RF ports with a fully integrated solidstate switch matrix, allowing fast and wear-free switching between the different ports and thus the different test devices.

While the signal output can be routed to one or multiple ports at the same time to precondition the test device, the analysis part takes the data for one port at a time. When equipped with two transceivers, both analyzers work in parallel and record signals from two different devices simultaneously.

To simplify the programming and handling of the integrated switch matrix, the smart channel option provides as many as eight virtual instruments. All handling, scheduling and switching between the ports is done automatically to maximize resource utilization and speed.