R&S®Essentials | DC Power supplies fundamentals

5 reasons to use an SMU

Author: James Lewis l Test & Measurement expert and blogger

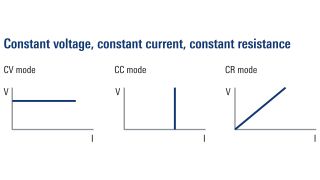

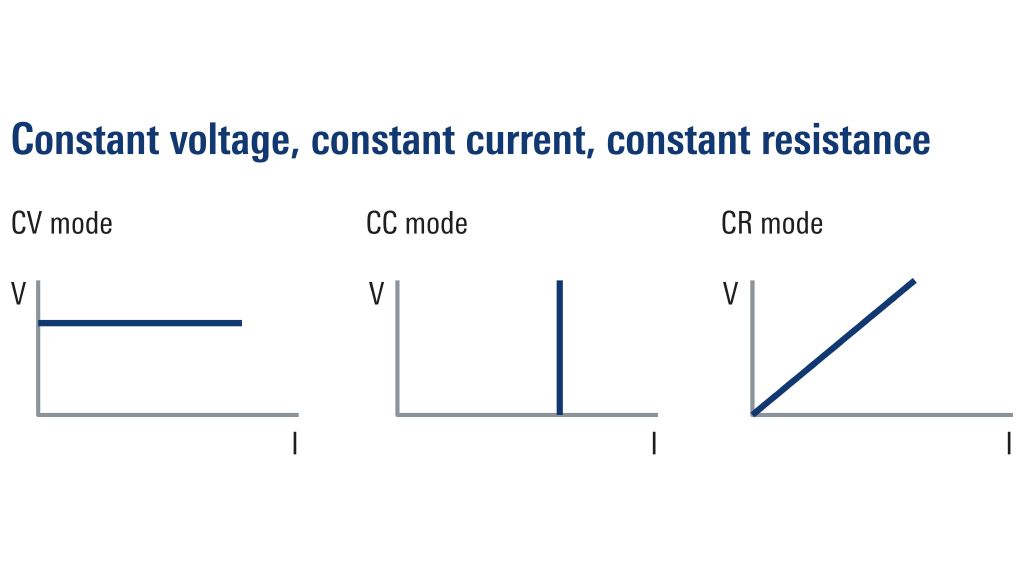

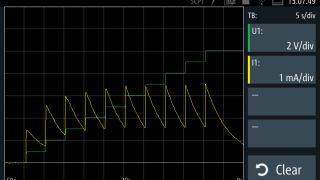

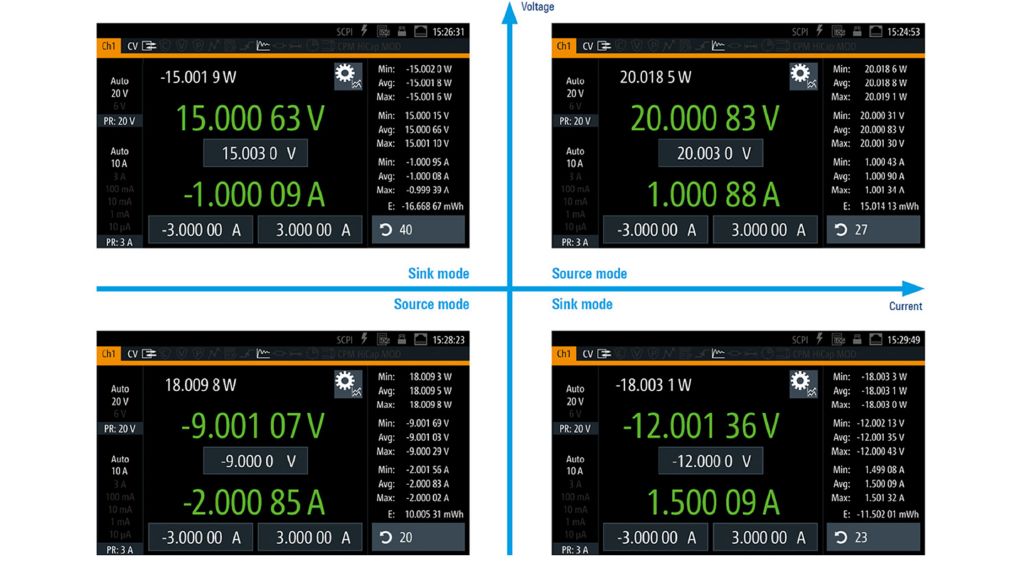

Source measurement units (SMU) serve as versatile instruments for electronics testing and measurement. They are adept at accurately measurement voltage and current and can function as power supplies and electronic loads. Their flexibility makes them especially valuable for engineers working with IoT and wireless devices.