Network tests pave the way for smart factories

5G has everything future smart factories need for wireless connectivity, but network tests are essential

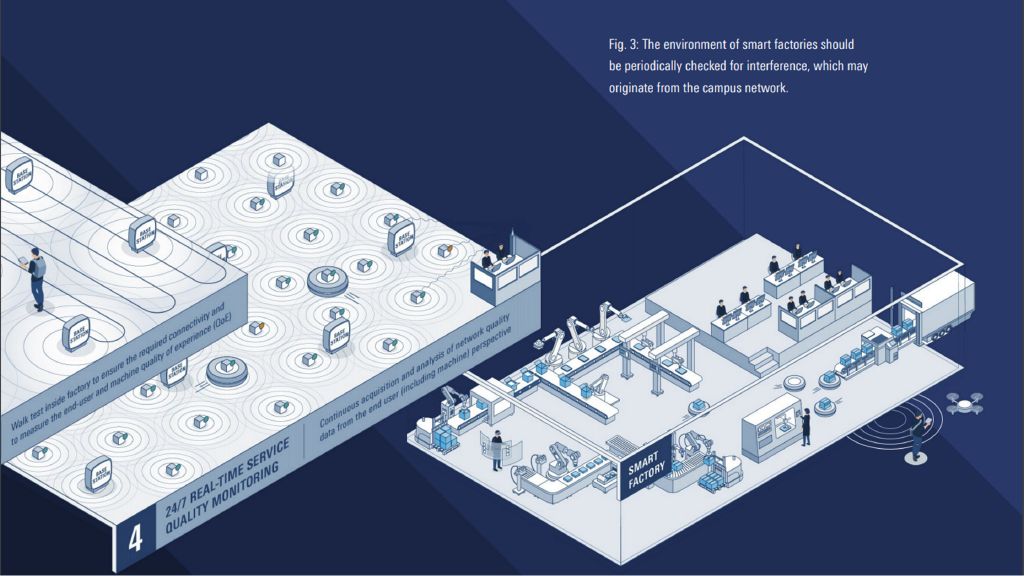

3GPP Release 15 standardized 5G technology is the basis for current 5G networks. Significant improvements in latency, network synchronization and industrial Ethernet network integration are expected from Release 16, which the 5G Automotive Association (5GAA) and the 5G Alliance for Connected Industries and Automation (5G-ACIA) have played a strong role in shaping. The release helps 5G evolve into a technology suitable to meet smart factory requirements (Industry 4.0). These requirements are characterized by data driven real-time control of all processes and the quick and flexible reconfiguration of production lines. Full connectivity of machines, people, plants, logistics and products is only feasible with wireless technology. Fast wireless 5G based links will be the nervous system coordinating the complex factory structure. Even a brief data flow interruption can have serious consequences and high costs, meaning the wireless network must be designed, set up and monitored with great care. The process requires several phases (including testing), as described below.