Your BMS testing challenges

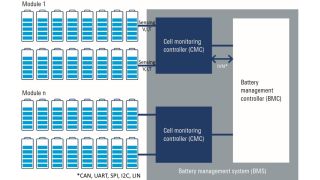

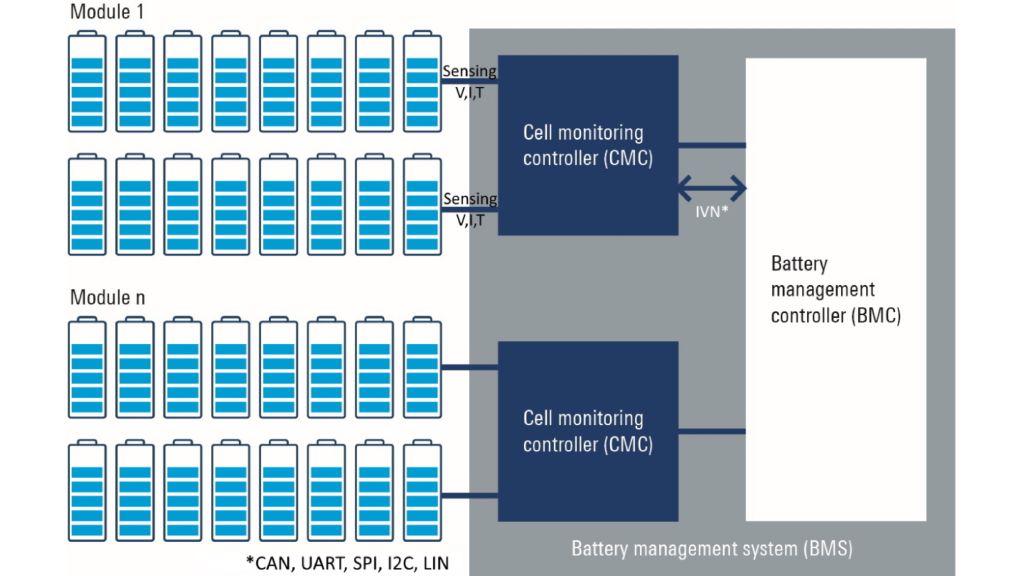

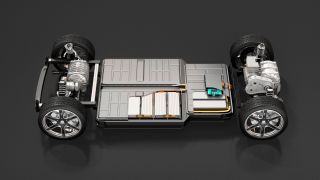

To optimize the monitoring, controlling and management of the battery cells using the BMS. For example, overcharging and deep discharging reduces the lifetime of the batteries, so correct control by the BMC must be ensured:

- Battery defects could lead to overheating of a battery and even cause a fire, so stress testing of the battery by emulating real-world conditions, including error scenarios such as overload and under-voltages and complex cell profiles should be conducted.

- CMC suppliers need to characterize the controller and perform production tests with flexible cell emulation.

- Validation of the complete BMS system including software simulation and HiL testing.

- Conduct cell balancing testing: emulation of pre-defined State of Charge (SoC) for each single cell.

Verify communication between the CMC & BMC, in accordance with the appropriate standard, e.g. CAN, LIN SPI etc.:

- Need to analyze many frames for a long period of time, identify certain frames of interest out of all frames transmitted on a bus

- Measure frame spaces: (frame to frame, trigger to frame, gap time etc)