Rohde & Schwarz solution

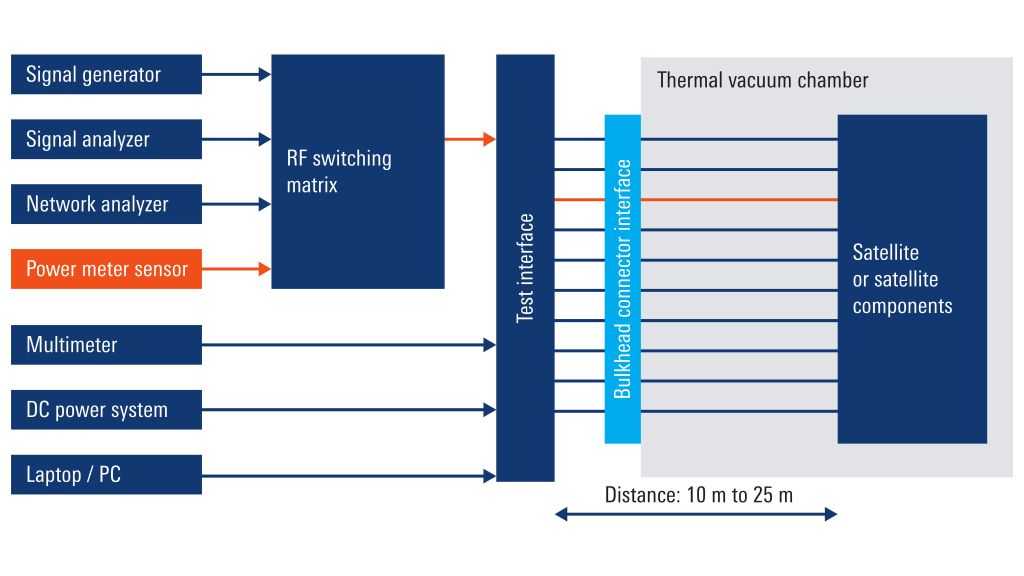

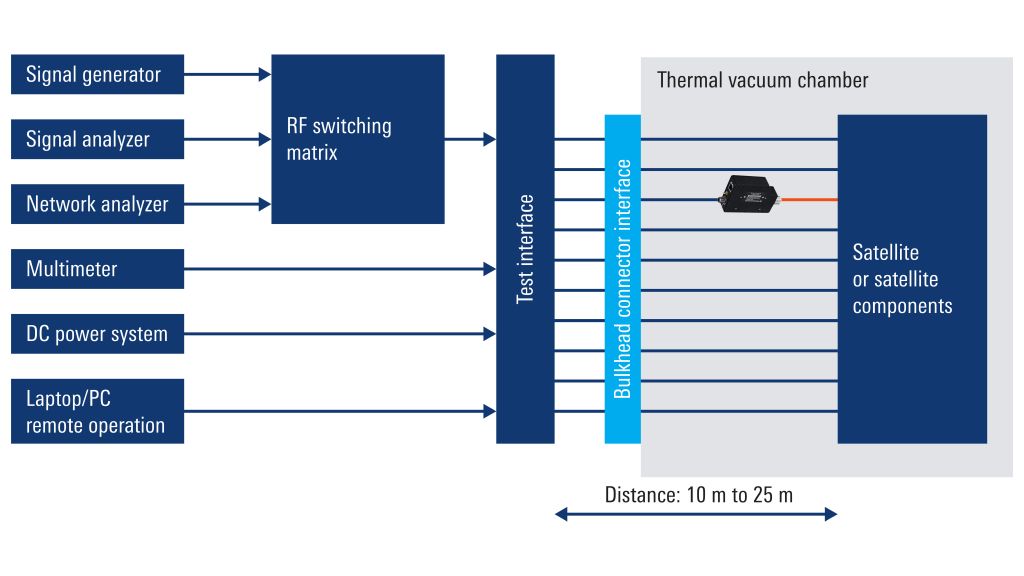

New technology makes it possible to put the sensor close to the DUT where it belongs. Putting the sensor inside the TVAC (see next page) eliminates contamination risk and greatly enhances measurement reliability and speed.

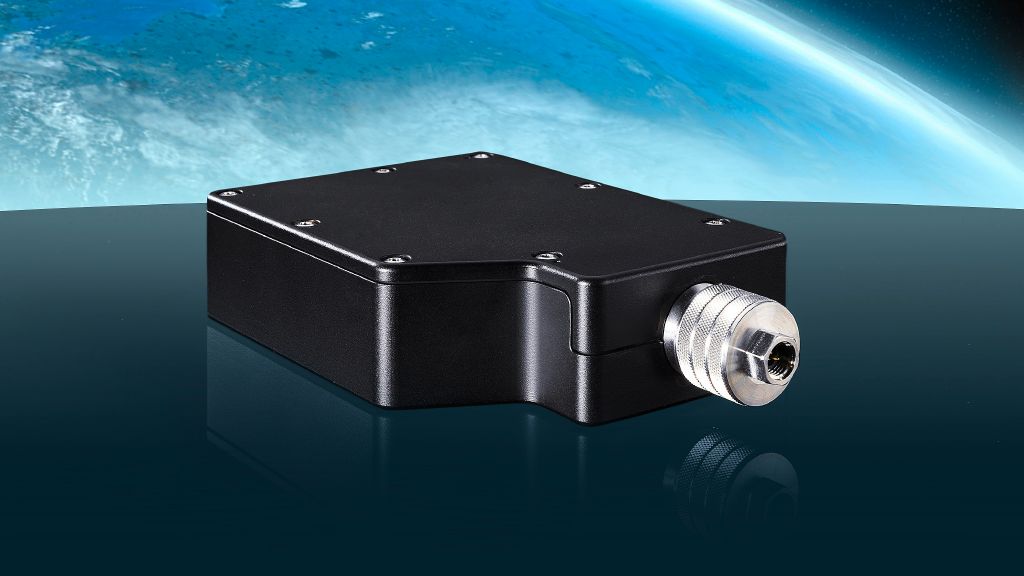

The R&S®NRP33SN-V and R&S®NRP67SN-V TVAC-compliant power sensors and their accessories are specially designed to fulfill thermal vacuum requirements. All components are baked in a vacuum chamber during the production process to reduce outgassing to a minimum. Venting holes in the housing ensure pressure equalization between the inside of the sensor and its environment, and threaded mounting holes ensure easy and safe mounting. In addition, matching digital LAN cables with a feedthrough option are made of vacuum-friendly materials, baked and shrink wrapped to prevent contamination.

This new approach enables the sensor to be directly connected to the satellite or component I/O inside the TVAC. This greatly improves accuracy by eliminating long RF cables that cause temperature-dependent changes in insertion loss and SWR. Accurate power measurement readings can be taken directly from the power sensor without going through lengthy and complex calibration routines.