Minimum total cost of ownership

A holistic view of costs

Total cost of ownership (TCO) is a figure that identifies all costs associated with capital equipment prior to purchase. It includes acquisition costs and all subsequent costs over the lifetime of the equipment, including repairs, maintenance and power consumption. The TCO also includes the direct and indirect costs.

Directs costs of a high frequency high power transmitter

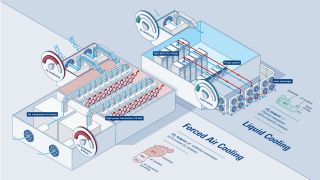

The direct costs for a high frequency (HF) high power transmitter include its costs along with the infrastructure needed for its operation, such as the building housing the transmitter, the physical power supply, the cooling systems and the control equipment. Other direct costs include installing and commissioning the transmitter and the infrastructure associated with the maintenance and servicing of the power supply.

Indirect costs

Indirect costs can result from unproductive or inefficient equipment usage. A user might need to keep a transmitter operationally available at all times and have back-up systems. These are typical indirect costs.